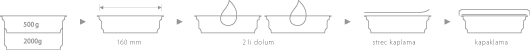

SD160-02 Yoghurt Filling Machine is manufactured by 10-year experience of our company. It was designed to meet the machine needs of the companies to perform practical, serial, safe and economical manufacturing. The machine also provides food safety due to its labour saving by practical and fast operation, filling and packaging untouched by human hands. Thanks to the detection sensors of the machines, full/empty bowl, folio/non-folio bowl are detected and the loss of wastage is minimized. Thus, manufacturing can be performed in a practical and economical way. SD160-02 aims to become a means of growth for the developing companies and more integrated plants.

SD160–02 is equipped with PLC system, Pneumatic system and Servo motor. Furthermore, the machine is covered with plexiglass plastic glass and its metal components are manufactured from 304 stainless steel. The machine has CIP unit, therefore, it can perform cleaning in an effective manner It can perform manufacturing in conformity with ISO 22000 Food Safety Management System and the international food manufacturing standards.