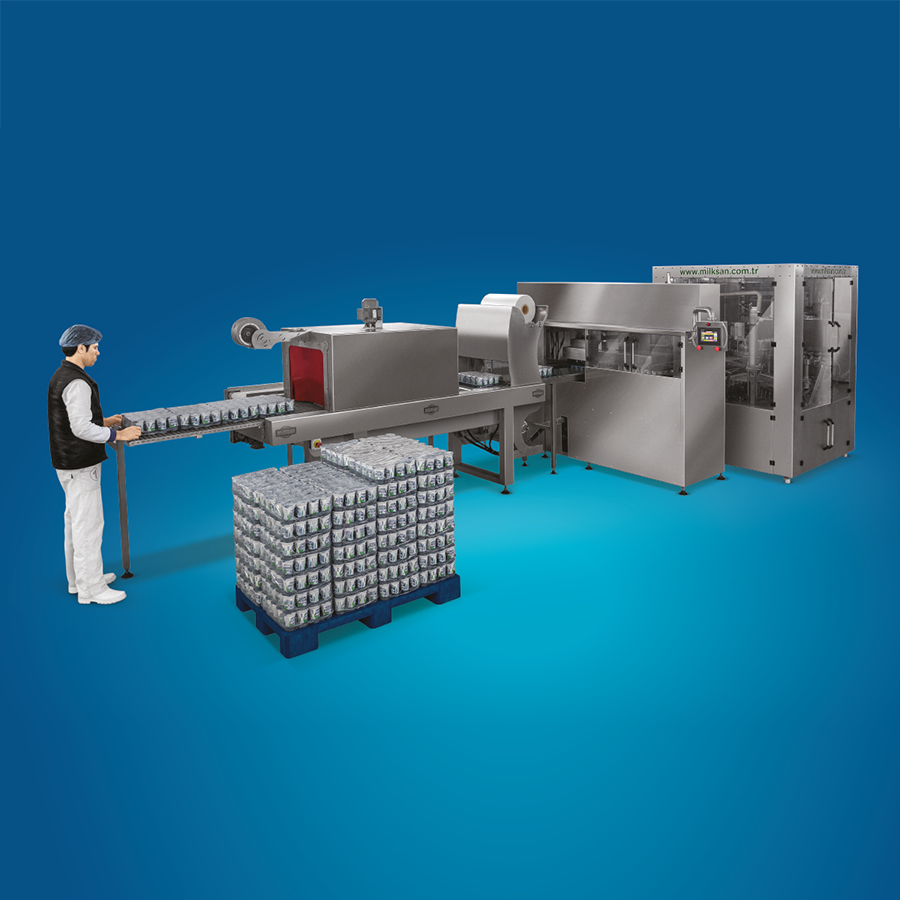

We have designed the robotic, buttermilk filling, grouping, collecting and shrinking machine ADG75-06 as a machine which will provide that the companies can make production in an effective, efficient, and fast way having high capacity and that will provide savings from the labor force.

ADG75-06 has been produced of aısı304 stainless steel in all units including the shrinking unit not only at certain points. By this way, the new generation ADG75-06 machine is an investment tool that will provide production easiness to its customers, and the possibility of finishing the work in due time and making the production process as more effective and result oriented.

With this machine, the filling, grouping and collection and then the shrinking of the glasses are realized continuously along the line and automatically without touching of the hands.

ADG75-06 is equipped with the plc system, Pneumatic system and Servo engine. Also, the machine has been covered with the Plexiglas plastic glass. The machine can be adjusted to the cip system. It can make production in the standards of the iso 22000 Food Safety Management System and international food production standards.

With ADG75-06, we are presenting more practical, secure, fast and economic product to the food sector.