We have designed a smart Buttermilk Filling Machine which will meet a considerable need of the food industry and provide your enterprise with a technology in the international level thanks to its advanced functions.

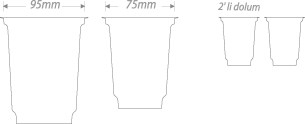

By AD95-02, it is aimed to minimize the high amount of wastage which occurs in 75-95 mm diameter group of glasses in old type models (semi-automatic systems). Thanks to its colour touch screen, programmable logic control (PLC) and integrated sensors, defective package purchase and uncovered filling has been prevented and these properties have been functionalized with an alarm signal. The machine is able to stop automatically in case it is exposed to any external hindrance during the filling process. Pneumatic system and Servo motor equipment have been used in the machine. Thus, it is aimed to perform quick filling. AD95-02 filling system can perform 3100 fillings per hour. This design logic developed in the machine is specific for good manufacturing practices. CIP system can be applied in the machine and the amount of wastage is nearly zero and packaging can be made untouched by human hands; thus, manufacturing is performed in conformity with ISO 22000 Food Safety Management System.